Back in March, I left my job with ConocoPhillips to become the Engineering Director for London-based Accsys Technologies, PLC (but my work is focused within the wholly-owned Titan Wood subsidiaries). I explained the circumstances behind my decision to switch employers here. I stated at that time that I would continue to focus my writing on energy and the environment, and not use my platform to start promoting my new company – even though it is focused on environmental technologies. I think it’s fair to say that I have kept to my word. However, I did say that at some point I would write a more extensive article on exactly what it is that my new company is doing. This is that article, with ties into energy, the environment, sustainability, and carbon capture.

A Brief Chemical Tutorial

In a nutshell, Titan Wood chemically modifies fast growing softwood species like (but not limited to) Radiata pine in a way that results in their performance characteristics being superior to some of the best tropical hardwoods such as teak. It is important to note that the modification we make is at the molecular level; we do not impregnate the wood with chemical preservatives that can leach out into the environment. Wood treatment processes like Chromated Copper Arsenate (CCA) fall into this latter category. Further, disposal of treated wood can be a nightmare, as many treatment processes result in the wood being classified as hazardous waste.

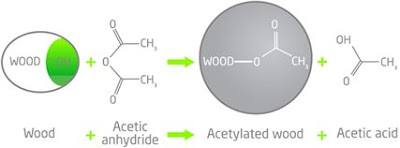

Following is a brief explanation of the science behind our process, in mostly layman’s terms. Wood is a very complex material, composed of many complex organic polymers (very long-chain carbon compounds). There are also numerous hydroxyl groups (OH) within wood. Think of a hydroxyl as 2/3rds of a water molecule (HOH, or H2O). Hydroxyl groups are very prone to attracting and releasing water, which is the primary mechanism by which wood shrinks and swells (and this of course makes paint crack and peel). Wood also naturally contains acetyl groups. An acetyl group is essentially an attached acetic acid molecule. Most of you are familiar with acetic acid, because you sometimes put it on your salad in the form of vinegar.

What we do in our process is remove a large fraction of those hydroxyl groups and replace them with acetyl groups. We call this wood ‘Accoya® wood’, and the properties are remarkably different than the unmodified wood we started out with. Dimensional stability, durability, and UV light resistance are all dramatically improved. Because Accoya absorbs less moisture, thermal insulating properties are also better. Further, Accoya is resistant to attack by termites, microbes, and fungi. Accoya is virtually rot-proof, and yet non-toxic.

Consider the implications. Instead of deforesting tropical rainforests for the highest quality hardwoods, we can essentially make them from trees that grow in northern climates. Wood that is grown via sustainable forestry practices and modified with our acetylation process provides a far more sustainable model for producing high-performance lumber. If the wood is both grown and used locally, so much the better.

How Accoya Sequesters Carbon

That alone is a pretty good story, but there’s more. As we all know, greenhouse gas emissions continue to rise. The recently released World Energy Outlook from the IEA forecast that carbon dioxide emissions from coal combustion would rise from 11.7 billion metric tons in 2006 to 18.6 billion metric tons in 2030. The IEA further predicted that carbon sequestration applications will have limited potential to influence carbon dioxide emissions by 2030.

If we are to slow or halt our carbon dioxide emissions, we need a combination of lower reliance on fossil fuels, coupled with commercially viable carbon sequestration, or carbon capture and storage (CCS) technologies. But the problem with carbon sequestration technologies is that either 1). People can’t figure out how to make money with them, so they aren’t commercialized; or 2). The carbon sequestration is fleeting.

For example, carbon dioxide can certainly be captured from the stacks of coal-fired power plants. A number of technologies will suffice, but they will all add to the cost of electricity. Estimates are that carbon capture would add 25% to the cost of producing electricity from coal. Unless large numbers of consumers are willing to pay this cost – or unless governments mandate it (and therefore mandate that consumers will pay the additional costs), adoption of these sorts of CCS technologies will face strong headwinds.

What about the use of CO2 in enhanced crude oil recovery operations? There are some applications for this, but they are limited. You must still capture and compress the CO2, and then you have to get it to the oil field. Further, that CO2 is being used to produce more oil, which will subsequently produce more CO2. A similar situation applies to the schemes for using algae to capture carbon dioxide from power plants, and then turning that algae into biodiesel. While one could certainly argue that additional energy was produced for each CO2 molecule that was emitted (presuming the energy return is >1.0), at the end of the cycle the CO2 originating from the coal still ends up in the atmosphere.

However, I believe Titan Wood has a truly commercial carbon sequestration application. To my knowledge it is the best (only?) commercial solution in existence. Here is why I believe that.

You know that when a tree grows, it extracts carbon dioxide from the air, converts it via photosynthesis into various biopolymers, and stores the carbon as wood, leaves, etc. Left alone, a tree will uptake carbon dioxide as it grows, but it will eventually die and decompose, returning the carbon dioxide back to the atmosphere. If you could instead take the tree and just bury it deep within the earth, the carbon would be sequestered. This is in fact similar to how all of the carbon in oil, coal, and gas got sequestered in the first place. Ancient plants and animals died and were buried, and the heat and pressure of the earth turned them into fossil fuels.

Of course one can’t make money by growing trees and burying them. So, what else can you do? You could build with wood, and that also sequesters carbon during the lifetime of the application. Because Accoya is modified to resist rot, the carbon can be sequestered for much longer. That’s appealing, but it isn’t the most compelling argument. In fact, you could make that same argument about wood that is treated with toxic treatments – it can sequester carbon for a long period of time (with the obvious negative of the chemicals leeching into the environment).

No, the really compelling aspect about Accoya is that the improved characteristics make it a viable replacement for metals, plastics, and even concrete in certain applications. You can take a very fast growing tree like pine, and modify it so that it can not only replace tropical hardwoods, but it can in some instances replace the steel in a bridge. That’s where the carbon sequestration potential comes into play.

Imagine that instead of making window frames out of plastic (which comes from a fossil fuel) or aluminum (which requires a lot of electricity to produce), you made them out of Accoya. Not only have you avoided carbon emissions, but you have sequestered carbon in a long-lasting application.

Imagine that instead of constructing a bridge out of steel and concrete (both very fossil-fuel intensive), you made it out of Accoya. Again, you have avoided carbon emissions, and you have sequestered carbon. Note that neither of these scenarios is hypothetical. Accoya is currently being used in window frames, and a pair of heavy-traffic bridges is under construction right now in Sneek, the Netherlands. Kudos to the Dutch government for their foresight. The first bridge has been completed and is shown in the opening picture. (See this article for more information). Bear in mind that this bridge is certified to support 60 tons, making it the only wooden bridge in the world certified to support such a heavy load. That makes it the first of its kind.

(As an aside, in 1988 the U.S. Congress passed the Timber Bridge Initiative, to promote the use of timber in bridges. This initiative currently resides at the Forest Products Lab of the U.S. Forestry Service, but we have not yet been in contact with them regarding the possibility of building Accoya bridges in the U.S.)

What is the potential for carbon sequestration? I have done some calculations on that, shown below.

Carbon Sequestration Potential of Accoya

Per this reference:

According to analysis by JATO Dynamics, CO2 emissions in the top five markets dropped by 0.3 g/km in through the first seven months of 2007 compared to the same time last year. A volume-weighted average of new cars sold in the period yielded an average of 160.5 g/km for the fleet.

That means that the average European car emits (160.5/44 g CO2/mol) = 3.65 moles CO2 per km traveled.

The density of Radiata pine is roughly 500 kg/m3. According to University of Wisconsin Professor Emeritus Roger Rowell (and from other sources I have checked), carbon represents about 50% of that, or 250 kg/m3. In chemistry speak, that is (250,000 g/12 g mol) = 20,833 moles of carbon per m3 of wood, which is equal to the number of moles of carbon dioxide that were removed from the atmosphere.

Our Arnhem plant has a nameplate capacity of 30,000 m3/year of finished wood (and the next plant will be much larger). Then the carbon sequestration potential from the Arnhem plant is 20,833* 30,000 = 625 million moles of carbon per year.

Put in terms of the average European car, that means that the output of our relatively small Arnhem plant could sequester the carbon emissions of 625 million moles/(3.65 moles per km) = 171 million km of driving. The average European drives around 11,000 km/yr according to this chart. This translates to sequestration of the carbon emissions of 171 million/11,000 = 15,545 cars per year.

I am not aware of any other technology that can make this claim.

Conclusion

I believe we have a good story in Accoya. I barely scratched the surface of the advantages, which extend to painted surfaces lasting much longer (more avoided emissions, and less fossil fuels for paint manufacture). Our plans at present are to continue to manufacture Accoya in the Netherlands, and to license the technology. The second Accoya plant is being built by our licensee, Diamond Wood, in China. The third plant will be built by our licensee Al Rajhi in the Middle East. Serious discussions are taking places with other prospective licensees around the world, including several in North America.

The nameplate capacity of our first plant in Arnhem, the Netherlands, is 30,000 m3 of wood/year. This output can potentially sequester the carbon emissions of over 15,000 cars per year in Europe. The total offset is equivalent to an annual distance driven of 171 million km. Note that this presumes that we have used Accoya in an application that normally uses metal/plastics/concrete, etc. It does not take into consideration the fact that our life-cycle-assessment (LCA) shows that the energy inputs into producing concrete, steel, etc. are also higher than for producing Accoya – nor that we are avoiding the harvesting of tropical hardwoods. In other words, I believe this should be a conservative estimate.

While I have given you the technical spiel, I am not the guy to answer questions about licensing, sales, etc. If you want some information along those lines, please contact Starla Middlebrooks (Starla ‘dot’ Middlebrooks ‘at’ titanwood ‘dot’ com) at our Dallas offices.

Questions and (My) Answers to Various Inquiries

People have asked me lots of interesting questions around the company and the product. One sort of funny story related to this is that at this year’s ASPO conference in Sacramento, I escaped the talks a bit early to have a quick bite, as I was on an evening panel session. A few minutes later, Bob Hirsch walked in and asked if he could join me. I was delighted, and thought I would get to quiz him about The Hirsch Report. Instead, he spent the next half hour asking me all sorts of questions about Accoya. We were joined by Kjell Aleklett, and he also wanted to talk about wood. After we finished talking, I reflected on how funny it was to have the three of us sitting there, all passionate about oil depletion and energy in general, and all we talked about was wood.

Anyway, here are a few of the sorts of questions that seem to come up most frequently.

Q. Doesn’t the process itself use a lot of energy? A lot more than say, planting a tree and waiting a few years.

A. No. When you grow a tree, like a fast-growing softwood, what happens? It either grows to maturity, eventually dies, and releases its carbon dioxide back to the atmosphere. Or, it is cut down and used in an application that results in it releasing its carbon back to the atmosphere in much less than 100 years.

What happens with Accoya is that you can make a harvest every 20 years and put it into a long-term application. When you put it into an application that is typically aluminum or steel, you have a dual-win: It takes less energy to make Accoya, and you have sequestered carbon where you would have placed steel.

Of course you also have a big benefit by using it for applications typically reserved for tropical timber in that you displace tropical timber with softwoods.

Q. Can Accoya eventually be cost-competitive with other treated woods?

A. That depends on what you mean by cost-competitive. Is it as cheap as arsenic-treated wood? No, but arsenic-treated wood is toxic and disposal is problematic. Likewise, there are similar issues with other cheap wood treatments like pentachlorophenol, creosote, borate, etc. Accoya is no more toxic than regular wood. There is no toxic residue from the treatment.

Q. Seems ironic. Other treated wood is less likely to be burned at the end of its structural life, so the toxic wood is actually more likely to sequester carbon for more than 100 years than is the Accoya, even if the toxic wood is otherwise worse for the environment.

A. No, as that misses two key points. You touched on one in your last sentence. The reason toxic wood eventually fails is because it has leached its components out into the environment. So it continues to decompose at the landfill, albeit at a slower rate than normal wood.

But the key point is this: The acetylation treatment not only makes the wood resistance to biological attack (as do toxic treatments), but it also imparts other beneficial characteristics to the wood, which is the real bonus.

Toxic treated wood doesn’t become more dimensionally stable. A toxic-treated pine is still a softwood. An acetylated pine becomes comparable to a tropical hardwood. The durability and dimensional stability of Accoya exceeds that of teak. See here and here. Now you can go build bridges out of it, something you can’t do with the toxic treated woods. Thus, the acetylation opens up new applications, so there is much greater carbon sequestration potential.

Q. OK, I give. What’s the catch?

A. The ‘catch’ is pretty straightforward. Accoya is obviously more expensive than untreated softwood. And unless customers understand the whole story, they may opt for a cheaper, but inferior option. My job as Engineering Director is to make sure we are running our process in the most efficient manner, and therefore keeping our costs at a minimum.

The other catch is that the market for building materials is presently pretty poor, as a result of the overall economic crisis. So we are swimming upstream against that current.

Q. So are you saying that this is the solution to rising carbon dioxide emissions?

A. It can be a tool in the arsenal. It may be the only tool in the arsenal at present. (If you believe there to be other practical carbon sequestration applications, please let me know and I will amend this). To make a bigger dent in carbon emissions, we would need to start replacing more metals and plastics with Accoya (wooden refrigerators, anyone?).

You can find answers to lots of other questions in our FAQ. Now back to your regularly scheduled programming (even though I think the subject matter here is topical).

Note: As always, if you spot any errors, please call them to my attention.

Humans contribute about 5% of CO2 emissions,while decaying biomass contributes over 40%. Using 10-12% of the biomass that would otherwise decay in long-lasting applications would be enough to offset human activity. That’s an enormous amount of wood Robert. But every board helps….

Maury, I have done some calculations on what it would take to offset all emissions from human activities. You are correct; it’s a lot of wood. I don’t think most people who argue for a drastic cut in carbon emissions really understand the scope of that issue.

But as you say, every board helps.

Cheers, Robert

Very cool. Wish I could go buy some here in the southern US.

Durable construction should receive more attention in sustainability discussions. Homes around here are built to sell, not to last.

A few thoughts:

1. Beware the “land use tax” – plantation forestry can either result in clearing of existing natural forest habitat or displace other land uses, resulting in further conversion of natural forests and concomitant biodiversity and carbon loss. Sourcing certified sustainable wood can help, at least up to a point, but be sure to give a realistic sense of what the actual carbon bottom line is.

2. Has the Accoya process been tested on bamboo? This may produce the biggest carbon bounce per unit of land.

Outstanding !!!!

Electricity in Nebraska is produced by public utilities.

The largest of these is NPPD. At a recent technical session they indicated that 62% of the states electricity was made by coal plants. They expect the future to require CO2 capture.

I suspect this is a big issue to them.

RBM

I’m a little out of my element here, but what are the growth rates for your softwood pine species?

Several organizations have successfully engineered trees that have superior growth rates compared to native species, so I’m curious if there is a way to “double up” the environmental benefits here.

My high growth rate example would be the Oak Ridge National Labs research with the GM hybrid poplars.

Has the Accoya process been tested on bamboo? This may produce the biggest carbon bounce per unit of land.

John, without going into detail, bamboo has definitely been on the table. We have a testing facility and run quite a variety of materials through.

Cheers, Robert

I’m a little out of my element here, but what are the growth rates for your softwood pine species?

Generally about 20 years, which is a much faster turn around than the tropical hardwoods.

But elaborating on your idea, if a species could be genetically engineered to be both fast-growing and to have a high naturally occurring acetyl content, then you have something that can sequester a lot of carbon quickly.

This was one of the first questions I asked before I came on board: What is the potential for a tree genetically engineered for a much higher acetyl level to come in and take our market?

Cheers, RR

Considering that Obama is talking about big investments in infrastructure in the near term in America, the economic crisis might not be as big a factor for you in the next couple of years. I’d love to see more wooden bridges like the one in Sneek, rather than the ubiquitous jungles of concrete and steel you find in most American cities.

Biochar is a promissing approach to sequester a lot of carbon in soils and increase soil fertility simultaneously:

http://www.biochar-international.org

There is a german start-up called TimberTower trying to get wood based towers for wind turbines into the market. Would be a good idea to comine this idea with your Accoya-technology.

http://www.timbertower.de

Hi

I’d like to know two things more about this that I haven’t noticed anywhere in available documentation:

Are the freezing properties of wood changed (e.g. teak and mahogany do not handle freezing well when their moisture content is too high, compared with local (nordic) softwoods)

Are the bending properties of wood changed in some manner?

I’m mostly interested in these for wooden boat building, especially in Nordic countries – local woods can handle freezing when moist to some extent but their durability otherwise is not as good as teak or mahogany. (Personally I’m not directly involved in boat building but I have some contacts that might be interested in this if the Accoya treatment makes local woods better…)

Thanks

Seppo Syrjälä

Finland

RR-

As you probably know, whole teak forest in SE Asia have been felled, due to the desire for pretty hardwoods.

It seems to me a a huge benefit of your process is that we get a hardwood w/o the environmental plunder (and if the teak forests can grow back, they will store CO2 for decades, and even centuries).

Can wood be stained after your treatment?

That might be the market — stain it to look like teak, which commands a hefty price indeed.

That being said, I worry more about the onset of another Ice Age than global warming…but each to his own.

What’s the net carbon balance on your process? Presumably there’s energy in the processing itself, as well as the harvest, transport, etc. That might be 5% or 50% of the embodied carbon in the wood, and that will have a huge impact on the actual potential for sequestration.

Another question in that vein: What is the typical mass of your material required in structural applications vs. the mass (of steel, etc) that is being replaced? That bridge looks like it used a LOT of wood.

The application you describe that I am most excited about is actually the window frames. Wood frames are among the best options thermally, but their durability is a problem. All the other solutions are some combination of thermally conductive (aluminum), toxic (PVC), or expensive (fiberglass). So a durable wood solution is exciting.

Greetings Robert

First thank you for providing the excellent summary of the features and benefits of Accoya Wood, you have a winner. Where water and sun (enviroment) meet wood will be big markets: decks, windows, siding, post, fences, rail road ties, etc.

Regarding long term (1,000 plus years) wood carbon sequestration, check out the Wikipedia link on Terra Preta (bio char in the soil).

http://en.wikipedia.org/wiki/Terra_preta

Best Wishes

“If you believe there to be other practical carbon sequestration applications, please let me know and I will amend this”.

Well, I think there is one (related to that Terra Preta mention of Shaun B’s just above), but let me beat the critics to it and admit that it wouldn’t sequester much, either as a proportion of the carbon involved or in total amount. But the question was whether it would be practical at all.

Particularly during the Second World War, many cars were modified to run off gasifiers. These were often fuelled with inefficiently produced charcoal. The inefficiencies included charcoal left in burning pits. And that waste was a commercial sequestration of carbon, since it is only recyclable by burning, weathering with sunlight and moisture, or through the very long term geological cycle.

Non-commercially, you could sequester a lot more carbon by deliberately making charcoal from renewable wood sources and burying it in landfills or sinking it underwater – but someone would have to pay for that.

Robert, Can this process be used on a composite material? The reason I ask is that I have heard that hemp fibers can be compressed to form a wood like substance. Hemp can be grown very quickly, would the acetyl content of hemp fibers be high enough?

Catching up on a number of questions. Thanks to all for the questions and comments. I should pull some of these into the Q&A at the end of the essay.

Are the freezing properties of wood changed (e.g. teak and mahogany do not handle freezing well when their moisture content is too high, compared with local (nordic) softwoods)

I had to ask about this one, and the answer I got was what I suspected. Because the equilibrium moisture content of Accoya® is much lower than other woods, we believe it should tolerate freezing quite well. But we are checking to see if we have any test data on file.

Are the bending properties of wood changed in some manner?

Bending properties (MOE) are very minimally changed.

Can wood be stained after your treatment?

Absolutely. Stained, painted, cut, glued – the same kinds of things you do with regular wood.

What’s the net carbon balance on your process? Presumably there’s energy in the processing itself, as well as the harvest, transport, etc. That might be 5% or 50% of the embodied carbon in the wood, and that will have a huge impact on the actual potential for sequestration.

GE, that is a very important question. We do have an LCA for Accoya®, but I don’t believe we have ever made that information public. We are in the process of getting additional LCAs that flesh out the carbon question in much more depth than the original LCA did. What the original LCA did was focus the energy to manufacture versus competitors like aluminum and PVC. The conclusion was that it takes less energy to make Accoya® than it does to make the competitors. But ‘less than a lot’ can still be a lot, so we are trying to go through and validate all of the energy inputs. Regardless of the energy inputs, if it takes less energy to make Accoya® than it does to make a comparable amount of PVC, then the sequestration potential is at a minimum the amount of carbon stored away in the wood.

The carbon issue is complicated by the fact that one can easily make choices that will reduce overall energy inputs. When we built our first plant, capital costs were a concern. So, we used natural gas to produce steam. In the future scrap wood could be used. In fact, I think I could design a process that could have zero fossil fuel inputs (into the actual process). It all comes down to capital costs.

What is the typical mass of your material required in structural applications vs. the mass (of steel, etc) that is being replaced? That bridge looks like it used a LOT of wood.

I have been asked that question now a couple of times. One thing to bear in mind is that there is a LOT of wood in the bridge, but a large portion of what you see is aesthetic. Your question would be relevant to the structural parts. I know how much wood went into the bridge, but not how much steel, concrete, etc. was displaced as a result. This is of course another very important question. If it took 3 cubic meters of Accoya® to replace 1 cubic meter of steel, then the energy inputs for Accoya® must be multiplied to compensate. I am not suggesting that this is the case, but I understand why the question is important. I will try to find an answer for you.

The application you describe that I am most excited about is actually the window frames.

That was actually the first market we entered. Our first LCA was done specifically to cover window applications. Performance of the windows has been great. BSW Timber in the UK is selling Accoya® windows:

Windows from Accoya

Can this process be used on a composite material?

I am not sure what we have out there in the public domain on this, so I will answer with a simple “Yes.”

Cheers, RR

Robert,

Congrats. Two thoughts:

1. Is this publically traded? 😉

2. A good application (at least for exposure) would be to supply bats for organized baseball. Those things are always shattering. But getting something like that approved will be a difficult process.

BBM-

Baseball bats. That is brilliant — especially as there are concerns that the metal bats result in a “too lively” ball. Plus, the “ping” of a metal bat will never sound as right as the “crack” of wood.

Now, if we can just get rid of the other bane of modern baseball, the wimp designated batter.

Robert, how does Accoya’s strength compare?

To what extent could you compensate for higher cost with thinner members?

Robert,

I have an of topic question. Obama has announced his energy and environmental teams today, what do you think of his picks?

I am not an expert, but I don’t think you don’t need to place the ® next to every instance of the word in an article. The first time is fine, as the mark is used, for your company’s protection, to alert the public of the trademark. That’s the point. In your post, the repeated use just detracts from the readability.

Also, since it is your personal blog, I don’t see why you feel the need to use the trademark symbol in the first place. Unless you think your blog is written at the behest of your employer. Which is isn’t. You make that clear in the post itself.

Regardless of what I wrote above, I don’t think you are using the ® symbol correctly. In prose, you should not place the mark when using accoya as a noun, only when modifying a noun (like: accoya® wood: good, accoya® process: good). If use of some trademarked words as nouns becomes common, a legal argument can be made for it being unenforceable against a competitor (if a company employee was the one who started the trend, that would be a headache.)

Also, since it is your personal blog, I don’t see why you feel the need to use the trademark symbol in the first place. Unless you think your blog is written at the behest of your employer.

You just resolved a big dilemma for me. It is company policy that when we write about Accoya, we do so as ‘Accoya® wood.’ As I was writing, I didn’t really like the looks of that repeated over and over, so I dropped the ‘wood.’ But the ‘®’ was very distracting from the essay as well. I debated dropping it off. It also felt like I was doing a commercial, and that isn’t my itent.

However, as you point out I am not writing this at the behest of the company. I wrote it on my own time, using information that is publicly available. Therefore, I think you freed me from all of those ® symbols. I am going to go back and change it, just leaving the first one intact.

Cheers, Robert

1. Is this publically traded? 😉

It is, but we have taken a beating just like so many other companies – especially in the building sector. We trade on the London Stock Exchange as AXS, and our current market cap is 234 million Euros.

2. A good application (at least for exposure) would be to supply bats for organized baseball.

That’s an interesting suggestion. I had not thought about that.

Cheers, Robert

Robert, how does Accoya’s strength compare?

The hardness slightly improves, and the strength is the same as the original wood. More information here. The real difference in strength would be noted as time progresses. Accoya would retain strenth and the base Radiata would lose strength.

To what extent could you compensate for higher cost with thinner members?

We are getting a bit outside my area of knowledge. I think that sort of calculation comes down to “How great must the strength and stability be at the end of the lifetime of the bridge?” Most woods are going to significantly degrade over a long period of time. So if the comparison is wood to wood, then I think you are correct.

Cheers, RR

Obama has announced his energy and environmental teams today, what do you think of his picks?

Paul, I am trying to get around to writing something on that. I wish I had done so right away, but time has gotten away from me.

Cheers, RR

Robert,

You have discussed the life cycle of wood and established it’s lower initial energy requirement when compared with the steel or concrete which it can replace. What’s not mentioned is what happens to accoya at the end of its life. Concrete and steel don’t last forever and both can be recycled into new buildings at considerably lower energy input when compared to extracting raw materials. Where does the accoya sequestered carbon go when removed from service? I doubt it can be recycled to the same degree that can steel, and I suspect it will end up emitted one way or another.

Perhaps heretically in this forum, I am much more interested in the mechanical and thermal properties of your product than its ability to sequester carbon. Do you have a quantitative chart comparing its density, yield stress, bending moment, elastic limit, and behavior in tension and shear with steel, aluminum, and other competitive materials? Does your process alter the thermal conductivity of wood as presently used up or down? Thank you for your response and interesting presentation.

Dr. Morton Grosser

Perhaps heretically in this forum, I’m more interested in the mechanical and thermal properties of your material than its ability to sequester carbon. Do you have a quantitative chart comparing its density, yield stress, elastic limit, bending moment, and behavior in tension and shear with steel, aluminum, and other competitive materials? Does the Accoya process change the thermal conductivity of wood as presently used up or down?

Thank you for your response and interesting presentation.

drmort@alum.mit.edu

Hi Dr. Grosser,

I can put our Director of Product Management and Technical Support in touch with you. He will have a lot of this information.

I can tell you that the thermal conductivity is lowered as a result of the process, which is especially desirable in window applications.

Cheers, RR

Where does the accoya sequestered carbon go when removed from service? I doubt it can be recycled to the same degree that can steel, and I suspect it will end up emitted one way or another.

Hi Bill,

The question has come up before. I think the question remains theoretical for decades. We really don’t know what the upper limit for the lifetime of Accoya will be.

Someone mentioned to me a couple of days ago that the bridge was designed for 80 years. So let’s say that 80 years from now, the bridge is coming down. If at that point we are still dealing with the problem of carbon emissions I can devise a number of schemes for recapturing the carbon in the wood. For instance, I can gasify the wood, turn it into acetic anhydride, and use that to acetylate a new batch of wood. I could burn it for process heat, displacing a fossil fuel. I could reuse it in a less demanding application. I could hydrolyze it to sugars and turn it into ethanol. I could gasify it and turn it into biodiesel. What I won’t have to do is to landfill it as hazardous waste, which is the end fate of wood produced by many preservative processes.

So the question isn’t whether it can be recycled. I think the answer is going to be dependent upon the conditions in place when we actually have to deal with the issue.

Cheers, RR

If the growth cycle for softwoods is 20 years and the resulting accoya product can last more than 80 years, that’s a substantial time shift for any end of life carbon emission that may occur. This would sure help carbon reduction efforts that need to happen sooner than that. I submit however, that carbon stored in wood does not have to be acetylated; a large amount of wood can be used in applications not requiring such exceptional weathering properties. I imagine that would be the case if wood-style carbon storage was somehow incentivized, only a portion would be accoya, owing to its higher cost.

Not that I don’t think it’s a good idea, I actually have a vinegar scented accoya sample that came in the mail; I may sequester a bit of carbon myself someday soon.

Congrats on your work.

The harvest cycle in British Columbia, Canada is closer to 40 or 70 for spruce/ pine/ fir, but I believe 20 years some places. Also, they only take limbed logs bigger than 10″. Therefore the slash that is left behind is significant (many 400m x 40m x 30m tall bonfires), maybe this would be a source of wood. Has the process been tried on small and chipped wood? Perhaps could be used in place of gravel? A growing medium? compost bins? laminates? siding on buildings? I assume higher surface area might make the process cheaper.

-Canadian treeplanter and student (kealandewit.gell@wur.nl)

Has the process been tried on small and chipped wood?

It has, but I am not sure whether we have published data on that.

Cheers, RR

Robert,

I honestly do not see how this can be considered a carbon sequestration method. Accoya may have an exceptionally long useful life, but it is organic, and at some point it WILL rot or burn. You can only call it sequestration if the carbon is permanently (as in forever) out of the cycle.

Brian, you can never say that carbon is permanently out of the cycle. Even the ancient algae that ended up as oil didn’t have its carbon sequestered permanently.

What you can say is that this process will tie the carbon up for much longer than normal wood. It will also enable carbon to be tied up in applications that would typically be filled by aluminum or steel. Therefore, you are buying time. We just don’t yet know the upper limit of how much time we are buying.

Think about a cure for cancer. Let’s say a cure for a specific form is 10 years out. If treatment today can help you live until the cure is available, then it isn’t really relevant that the treatment wasn’t a cure. The treatment bought you time.

Cheers, RR