As I noted in my earlier essay More Reality Checks for Algal Biodiesel, I initially had high hopes for the idea that we might make significant amounts of biodiesel from algae. A few years ago I read Michael Briggs’ essay Widescale Biodiesel Production from Algae and thought he put together a compelling case that algae could power our transportation system. I even exchanged a few e-mails with him at one point in order to get a better perspective on his views.

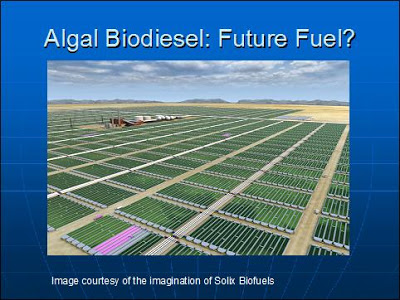

Ah, but the devil is always in the details. And as I dug into the details, my hopes began to fade. I had conversations with researchers who let me know what some of the problems were, and some were potential show-stoppers. Krassen Dimitrov’s analysis of Greenfuel Technologies and their algae claims strongly suggested that photobioreactors (PBRs), as shown in the slide below from my ASPO presentation last year (Biofuels: Facts and Fallacies), have no future.

Why? Because costs are about two orders of magnitude too high. More importantly, costs are tied to energy. That means that economic feasibility won’t come about if oil prices rise by one or two orders of magnitude. This is a show-stopper for the following reason. The amount of solar insolation falling on a square meter of land is known. The cost to build a square meter of PBRs is known. If, for example, a square meter of land might be expected to produce one gallon of algal biodiesel based on the sunlight falling on the surface, but the cost to build a square meter of PBR is $100, you have a problem. You can’t afford to spend $100 of capital to produce 1 gallon of biodiesel per year. (This is the thrust of Krassen’s analysis).

My previous essay hit on this, as Bryan Wilson, a co-founder of Solix, recently suggested they could produce algal biodiesel at a cost of $33/gal (because of very high energy inputs). Now comes a new report commissioned by the British Columbia Innovation Council (BCIC) et al. to examine the viability of an algal biodiesel industry in B.C. The conclusions were not optimistic. The full report (88 page PDF) is Microalgae Technologies and Processes for Biofuels/Bioenergy Production in British Columbia. I note that my friend John Benemann contributed to the report (and 3 people wanted to remain anonymous).

The study looked at photobioreactors (as seen in the graphic above), open raceways (something like a pond), and fermentors (as corn ethanol is produced). They estimated that the net cost of production per liter for PBRs was $24.60 ($93.23 US dollars/gallon), for open raceways it was $14.44 per liter, and for fermentors was $2.58 per liter.

Biodiesel Magazine also reported on the study:

A Sober Look at Biofuels From Algae

At least 15 companies are known to be pursuing the photobioreactor concept, mostly in Canada and the United States. There is no doubt that growing algae in photobioreactors is technically feasible since successful operations doing just that exist today. There are, however, serious challenges in making this process cost-effective for low-value products such as biofuels.

So, before throwing your money in with a company working on PBRs, make sure it’s money you won’t ever need again.

What about carbon credits? I have seen this mentioned as an additional benefit that might make the economics more favorable:

What about the value of sequestered carbon in algae-based biofuels? In short, there isn’t any. Atmospheric carbon is only sequestered for a short time until it’s burned in an engine. Under existing biofuels mandates in most industrialized countries, there will be no opportunity to sell carbon offsets unless fuel production is additional, or beyond such mandates.

But the technology will surely improve?

What about economies of scale or technology improvements? Economies of scale were considered in the analysis, using very generous assumptions. Some improvements could be made, including increased automation, genetically modified algae with higher oil yields and minimized light losses. On the other hand, the main components, such as concrete, glass and machinery, are unlikely to drop in price. Since there are limits to how much oil and starch algae can produce, the result is that photobioreactors can’t produce biofuels competitively today and are unlikely to do so in the future. It’s not slightly higher than fossil fuels, but by a factor of 10 to 15.

These results may come as a surprise to many. They were, however, confirmed by a number of independent sources. The study, although intended to examine the feasibility of algae cultivation for biofuels in British Columbia, has yielded findings that also apply to other regions and worldwide.

Sure, it’s in British Columbia, which is not the best place for year-round solar insolation. But double or even triple the amount of solar insolation and the economics don’t change enough to matter. So instead of producing biodiesel for $90 a gallon, you can produce it for $30. You still aren’t economical even if you could produce it for $5/gallon.

The fermentation concept appears to hold some promise, but if sunlight is not the energy source you need some other energy source that the algae can convert into oil. That doesn’t seem especially efficient, but they claim an energy balance of 1.93 (I think they can forget about that 2nd decimal point!) against only 1.23 for the PBRs. Still, 1.9 is on the low side of desirable, given that society is currently running off of an energy return in the 5-10 range.

What about using wild strains of algae in existing oxidation ponds rather than bio-reactors?

http://www.aquaflowgroup.com/technology.html

The problem is, among other things, that of scale. To have a significant impact on just about anything, whether it be stripping flue gas of carbon dioxide, or generating biofuels, the space that is needed to generate significant volumes is very large, if you are restricted, as most systems are, to a one foot or less thickness of water, since that is as far as the light will reach

I guess it all comes down to how “significant impact” is defined.

I agree that it’s highly improbable that biofuels could replace 80m barrels of oil a day.

Personally I think that much of that 80m barrels is likely to be replaced by electric transport.

Biofuels including algae may be able to supply a substantial amount of the remaining demand – i.e. jet fuel and manufacturing.

I’d be interested in seeing some back of the envelope math on how much biofuel could be produced using only already existing oxidation ponds.

If you consider that a “good” species of algae has 50% lipid content (some of our local ones are 25%) and that the pond is successful if it can achieve 50 gm/sq. m/day then you should be able to do the arithmetic. That rate, which has been achieved, and exceeded in controlled conditions, is generally assumed from a racetrack with about 6 – 12 inches of water in it

Even if the lipid OILS retrieved from algae cultivation were free and cost nothing – – most people still miss the most obvious point in the globally evolving alternative fuels equation.

And that is that these ‘biodiesel’ algae lipid OILS still float on this planet’s water bodies just like the Exxon Valdez OIL spill did and still does in Alaska’s Prince William Sound.

Water itself is utilized to clarify and isolate alternative ‘biodiesel’ types of plant or animal-based OILS.

This is the black and white difference here that most citizens and investors simply do not realize. And perhaps understanding this basic fact will become the near-term answer to climate change phenomenah?

New, alternative fuels systems producing bio-derived OILS does not make sense to me when I view brown urban smog as simply an OIL spill in the sky.

In layman’s terms, brown urban smog is uncombusted OILS coming out of car and truck tailpipes plus industrial smokestacks and cement kilns.

These uncombusted OILS do not subsequently dilute nor break down in this blue planet’s atmosphere of water vapor. Black and white here…

Any new biofuel to be produced on this planet must be BIOdegradable in order for it to truly succeed. And water solubility is the first basic criteria therein.

If Coskata were to produce ethanol from it’s gasification process using nasty bio-bugs to convert the mid-stream synthesis gas into ethanol (irregardless of cost), at least this C2 ethyl alcohol readily dilutes in water. Therein it feeds micro-organisms and plants with a free lunch and quite easily biodegrades.

This is a rather big difference from any type of OIL — whether it’s source is fossil crude, downstream refined petroleum products or the myriad of plant/animal OILS being pursued in this new ‘biodiesel’ arena.

These and nearly every form of fuel OIL are not readily biodegradable.

Algae lipid OILS at $33 to $90 per gallon isn’t going to make it! $5 per gallon isn’t going to make it!

This same Solix algae process is currently scheduled for some type of initial construction in partnership with the Southern Utes on their Tribal Reservation in S.W. Colorado.

The Ute’s are the new, prime investors in Solix migrating to s.w. Colorado from research labs at Colorado State University in Fort Collins. Valero Refining has bought into this firm as well for an undisclosed amount.

Should any level of algae OIL production commence, then these lipid OILS next have to be trucked 50 miles to a very small oil refinery in Bloomfield, NM, or 145 miles to another slightly larger oil refinery closer to Gallup, NM, or 333 miles over the Rocky Mountains to one of two oil refineries in north Denver to be processed and refined at additional costs into something resembling float-on-water diesel fuel.

Locals living in this S.W. Colorado region have wondered about the leftovers from this algae OIL squeezing process. And where is all the water going to come from to grow and then clarify and isolate these pressed bio-OILS?

Thanks for posting on this subject Robert – and especially in sharing the image created from “the imagination” of Solix biofuels.

The Southern Utes plus BP and Williams are offgassing hundreds of tons of CO2 per day which has been scrubbed from their copious coal-bed methane natural gas developments in this S.W. Colorado area.

Local press has reported that the Tribe was going to funnel some of this daily CO2 atmospheric emissions stream into the algae bioreactor growth beds to therein recycle a pinch of this daily tonnage of global warming CO2 pollutant to boost the green algae OIL’s growth cycle. Hurrah!

We’re talking green here although we don’t know what it means. Is it money? Is it the color of the algae? Is it the color of the soon-to-be new sky?

Solix’s CEO has stated that his firm hopes to obtain 3,000 gallons of algae lipid OIL per acre per year in optimum conditions. In refinery terms, a very, very small 15,000 barrel per day output capacity in comparison would necessitate 73,000 acres of green algae bio-OIL under cultivation and production on the Southern Ute Indian Reservation.

Considering that the So. Ute’s are building an uphill Lake just off their reservation, perhaps some other miracles might also occur in this region?

73,000 acres of algae ponds far exceeds the visual image which you posted.

Quite frankly, I don’t know where these thousands of acres of local land area would come from nor the workers to construct and/or operate such algae OIL production systems.

The research you’ve twice recently posted pointing to production costs of over $30 per gallon for algae OIL is a real wake-up call here. Thanks again for sharing with the broader publics so avidly interested in alternative energy…

Now the issue is how to interpret all of the interconnected nuiences therein. Maybe starting with biodegradable characteristcs first can winnow out the contenders to further review and wholeheartedly support?

Anonymous,

Your take on OIL is very interesting, but I look at it differently.

Because OIL floats on water, that means it must weigh the same as a duck, which means that it is made of wood (which also floats on water) and is therefore…..A WITCH!!!

And what do we do with witches???

BURN them.

So logically we need to burn all the OIL we can find.

I know it’s not much, but it makes a lot more sense than what you wrote.

Most raceway ponds are shallow becuase the light doesn’t reach too far through the water. The algae absorb more of the sunlight than they can use, and shade the ones underneath. Some mutant strains have been isolated that don’t absorb excess sunlight, increasing the depth the sunlight can penetrate. It’s not much, but it’s the start of the leap to overcome a big hurdle. And would it not be better to sort of ‘recycle’ carbon through algae, rather than putting carbon back out that was takin in millions of years ago?

To the Author-You really should read the follow-ups to case studies before you post evidence by quacks like Dimitrov. Here is a link to the follow-up study done by Dimitrov’s company, Nanostring Technologies: http://www.nanostring.net/Algae/CaseStudyFollowup.pdf

I find Appendix A to be the most intriguing part…

Don’t worry, I have read all of the exchanges between Krassen and GreenFuel. I guess the fact that GreenFuel is closing their doors means Krassen may have hit close to the mark.

RR