I have written periodically on ‘green diesel’, which should not be confused with biodiesel. Neste, Petrobras, and ConocoPhillips (in a venture with Tyson foods), have all entered the green diesel arena. (See a bit on the projects from these companies here; explore the green diesel stories I have written here).

Green diesel is produced either from hydrotreating or hydrocracking plant oils or animal fats (Neste, Petrobras, COP) or via the BTL reaction (Choren). Green diesel is chemically different from biodiesel. Green diesel has chemical properties identical to petroleum diesel, while biodiesel is not a pure hydrocarbon (it contain oxygen atoms, hence the somewhat different physical properties).

Today, Bob Rohantensky sent me the following story indicating that Neste just announced that they will build a facility in the Netherlands:

Neste Oil to build a NExBTL renewable diesel plant in Rotterdam

Neste Oil is to build an 800,000 t/a plant to produce NExBTL renewable diesel in Rotterdam in the Netherlands. Construction will start immediately and the facility is scheduled to be completed in 2011. Total cost of the investment is projected to be €670 million. Neste Oil announced its decision to go ahead with a similar-sized plant in Singapore in November 2007. Both plants are linked to Neste Oil’s goal of becoming the world’s leading producer of renewable diesel fuel.

NExBTL renewable diesel is based on Neste Oil’s proprietary technology, which can use a wide range of raw materials. In its plant in Finland, the company currently uses a mix of palm oil, rapeseed oil, and animal fat to produce renewable diesel. Offering excellent product quality – even better than fossil diesel – NExBTL can be used in all diesel engines.

Neste Oil has a major R&D program under way to develop new renewable raw materials for fuel production, and is working towards a target of completely non-food raw material use by 2020. Neste Oil is cooperating with over 20 universities and research institutions globally as part of this program, which is divided into six areas, including non-food vegetable oil, wood-based materials, and algae.

Regarding the NExBTL diesel, Neste says:

NExBTL renewable diesel is an advanced fuel based on renewable raw materials that performs more efficiently and has a lower level of environmental impact than fossil diesel or FAME-type biodiesel. Neste Oil requires its raw material suppliers to observe a responsible approach to sustainability. Feedstock of this type ensures that NExBTL renewable diesel has a 40-60% lower level of greenhouse gas emissions over its entire lifecycle compared to fossil diesel. NExBTL renewable diesel can be blended with conventional diesel fuel or used as such, and is suitable for all diesel engines.

Neste Oil is the leader in renewable diesel production. The company’s first NExBTL facility was commissioned in Finland at Neste Oil’s Porvoo refinery in summer 2007. Second facility is due to come on stream there in 2009. They both have a capacity of 170 000 t/a. In addition Neste Oil is building 800 000 t/a plants in Singapore and Rotterdam. Singapore facility is due to be completed by the end of 2010 and Rotterdam facility in 2011.

While this is an improvement, in my opinion, over biodiesel, they are still going to rely on oil crops such as palm oil. Destruction of rain forests in Malaysia and Indonesia to plant palm oil plantations poses a serious environmental threat. The future of green diesel needs to be based on non-food crops – especially those like jatropha that can be grown on marginal land – and waste materials such as biomass that is currently destined for landfills.

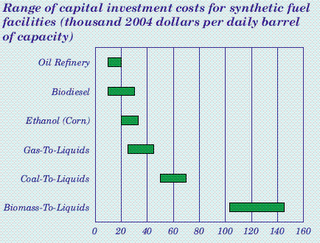

I am also curious about the costs per barrel. Let’s work that out. A barrel of oil weighs 0.137 metric tons (and has density similar to pure diesel). Then 800,000 t/yr is equal to 5.8 million bbl/year (16,000 bbl/day). For perspective, a mid-sized oil refinery will be around 250,000 bbl/day, but the Neste facility is certainly of a respectable size. The cost is projected to be €670 million. If I convert that to dollars, I can compare the cost to various other fuel technologies. A Euro is currently worth $1.53, so the project is going to cost US $1.025 billion. That works out to $64,000 per daily barrel. Again, for perspective the recently announced 400,000 bbl/day Jubail Refinery Project that Total is building with Saudi Aramco is currently estimated at $10 billion ($25,000/daily barrel).

Source: EIA Annual Energy Outlook 2006

To be honest, if Neste pulls the project off for that, it will come in at a competitive cost relative to other fuel technologies. See the above EIA figure for estimated costs of various fuel facilities. And that was from a couple of years ago, when stainless steel prices were significantly lower. So, on the one hand I hope Neste pulls this off, and on the other I hope they can source a different feedstock than palm oil for the plant.

I have previously mentioned Flax/Canola intercropped for fuel in a proper crop rotation. Flax (due to linseed properties) has an incredible resistance to insects and disease and if sprayed with pre-harvest glyphosate (Roundup) to dessicate and kill perennial weeds, it could be a very good part of crop rotation disease and weed control. Canola has a lot of problems with disease and when they lowered the erucic acid content, it made it very tasty to Bertha Army Worms, which wouldn’t touch flax. My Mom read Carrots Love Tomatoes, which is a companion planting/intercrop guide and since planted rows of flax between cabbage rows and it stops cabbage moths completely. The seeds are too close in size to separate them for food oil/industrial linseed, but if the product is being crushed for fuel it wouldn’t matter. If this was done in a proper rotation, it wouldn’t affect food production.

The sad part is that having grown several thousand acres of flax and Canola (separately) and between my brother and I custom sprayed close to two hundred thousand acres of pesticide on Canola and other crops, my opinion and ideas don’t have a PhD in crop sciences behind it, so no one really gives a crap what I think. This is a fundamental reason why our society is screwed. We need the Wright Brothers and Bucky Fuller, not academic research funded on the latest buzzwords.

While I’m ranting:

Another major problem with Canola is wild mustard and until genetically modified Canola (Roundup Ready, etc) that can withstand specific spray, you could only seed Canola on land that was very clean of wild mustard. Wild mustard wouldn’t be an issue at all if the seed was going for to green diesel, and regular Canola seed could be used rather than Monsanto’s (and other’s) genetically modified version that costs 10x more.

Neste’s NExBTL process is only one of many in the immediate pipeline that threatens to be cost-competitive with other fuel technologies.

Palm oil may give the best yields per acre now, but probably not for long. Algal oil may cost $20 per gallon to make now, but in a few years that cost will be well below $5 a gallon. What will the price of petro-fuel be then? It is not up to Neste or other bio-fuel technology companies to solve the rainforest problem.

This Neste plant costs about the same per daily barrel as an oil sands upgrader. Oil sands input is cheaper but Neste has lower CO2 emissions.

Bob Rohatensky–I read your posts with interest, and I don’t give a crap whether you have a Phd, or hit your head too many times on the barn post. What works, works.

If it makes you feel any better, for years those of us in the cabinet-furniture business have had to listen to specialists telling us what finishes worked. But you only really know when you apply the finish, and it is tested in market for several years. But you should read the magazines…..

OT; I hope these bio-diesel approaches work. RR has pointed ut mant times technical and economic barrers to real success. I am hoping jatropha works — one hopeful aspect: jatropha has never been selectively bred for yield. Corn was the size of your pinky when man first started planting it. If jatropha can be bred to increase yields, it may work. It has the advantage of not being plowed up every year. You plant once, and harvest for years, like palm trees. Like Bob R., I have no Phd, but I suspect annual plowing and planting, and growing is rather expensive.

What is most striking about the Neste process is not that its capital cost is low relative to CTL or BTL but that its capital cost is so high relative to oil refining: about 2 1/2 times that of a grass-roots complex refinery and about 10 times that of a refinery hydrocracker (a comparable hydrotreating process). What is there about hydrotreating palm oil or rapeseed oil that leads to such a high investment requirement?

btw Benny: In one of my previous lives, I owned a cabinet shop (specializing in short runs of furniture) in a rural area. Although overhead was extremely low and I only worked at it as a second job in the winter while farming, the economy was too depressed to support real furniture (death by Walmart). Grain/oil/potash prices are changing that here, but fuel/fertilizer/equipment are eating most of that up.

On the cost of Canola: If pesticide use and genetically modified seed isn’t required, it’s pretty realistic to expect a 35bu/acre Canola crop (40 is doable most years). Intercropped with flax, the flax isn’t very competitive so it wouldn’t affect much yield-wise in the Canola.

It should be feasible to keep input costs at around $100/acre (if there wasn’t an attempt to get food-grade Canola), plus about $40/acre for land costs in Western Canada and about $40/acre for harvesting.

Canola weighs 50lb/bu and is about 44% oil. That would be about 800 pounds per acre of oil, or about 90-100 gal/acre.

This document has some numbers, but RR wrote a chapter on biodiesel and probably knows them off-hand.

It should be possible to get the seed to a crusher for under $200/90 gal (per acre) or about $2/gal of oil and have the farming portion profitable.

Using food grade Canola: current spot price of Canola is at about $650/tonne and at 44% oil and 7.6 lb/gal that would be 127 gal/tonne or $5.11/gal.

The whole thing here is that as an example that if I had a 1000 acre farm and put in 100 acres (10%) of an oilseed for biodiesel, I would be able to get 9000 gallons of fuel. It would probably take about 1/2 of the 9000 gal. to farm the 1000 acres. The upside is that the farm would be a lot more self-sufficient, carbon neutral and still be producing food on 90% of the acres.